Possible designs of mullion and transom facade

Optics and design

The mullion-transom design can be used to create vertical facades, sloped facades and polygon facades, as well as panoramic facades with all-glass corners. As the most common designs for profiles, you can find the wood, steel, or cover shell optics.

Construction and arrangement of mullions and transoms

The typical profile face widths are between 35 and 60 mm.

There are several options when arranging mullions and transoms – the transoms can be in the same plane as the mullions, resulting in a flush appearance. The other option is for the transoms to be set forward or back from the mullions, creating a louvered façade.

Materials

The supporting framework of mullions and transoms and the pressure bars are made of wood, steel or aluminum. A combination of materials is also possible. Different materials can be selected as infill panels – from glass to sandwich elements to steel and aluminum. Glass facades can be realized with profile construction glass, cast glass or glass blocks – all types of glass are available as single, double or triple glazing.

Requirements

Special requirements for statics as well as fire, sound and heat protection are taken into account by different manufacturers. For example, there are solutions for increased static loads, suitable systems for passive houses or solutions with integrated photovoltaic system.

Manufacturers

Among the well-known and proven manufacturers of mullion-transom facades in Germany are Schüco, Raico, Hueck and Wicona.

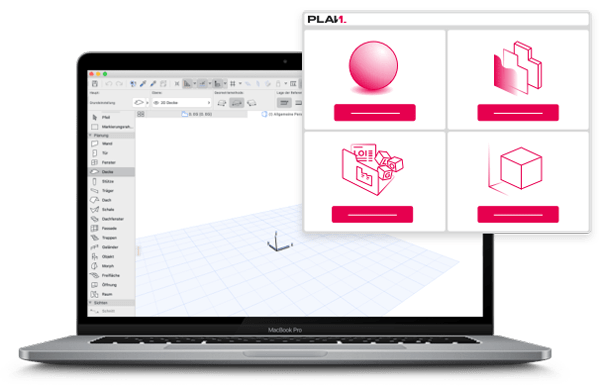

You can find these and other manufacturers directly on the Plan.One comparison platform. Within the product category Facade elements you will find mullion-transom facades under the filter Facade type. For this purpose, discover different manufacturers and their products. Additionally, choose between materials, such as alumnium, aluminuium wood and steel.